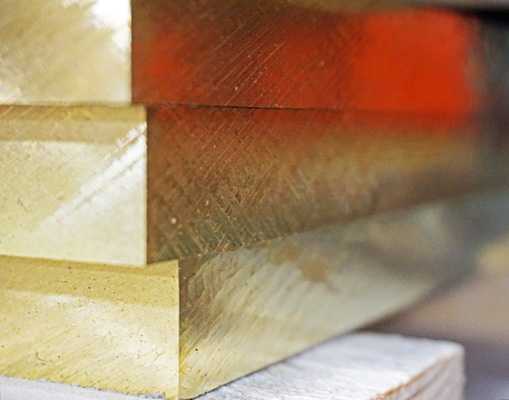

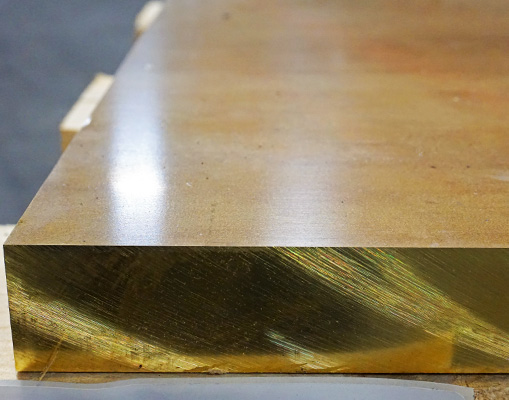

C46400 Naval Brass is copper, alloyed with zinc and tin to provide improved strength, corrosion resistance and machinability. As the name implies, naval brass has extensive marine application and can be found where strength and corrosion resistance are valued. Typical industrial applications for 464 brass include tubesheets, baffles, valve stems, fasteners and mold plates. C464 Naval Brass is also widely used for indoor and outdoor decorative applications. Naval brass is considered a Lead Free product because the maximum lead content is 1/5th of 1%.

Marmetal stocks C464 Naval Brass in Sheet, Plate and Bar form.

Specifications for C464 Naval Brass

| ASTM | ASME | Military | |

| Bar | ASTM B21 | ASME SB-21 | QQ-B-637 |

| Sheet | ASTM B171 | ASME SB-171 | QQ-B-639 |

| Plate | ASTM B171 | ASME SB-171 | QQ-B-639 |

Mechanical Properties for C464 Naval Brass

|

BAR – Round, Hex, Rectangular and Square

|

|||||

|

Commercial

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| M30 | All Sizes | 52 | 20 | 30 | |

| H02 | up to 1/2″ | 60 | 27 | 22 | |

| over 1/2″ to 1″ | 60 | 27 | 25 | ||

| over 1″ to 2″ | 58 | 26 | 25 | ||

| over 2″ to 3″ | 54 | 25 | 25 | ||

| over 3″ to 4″ | 54 | 22 | 27 | ||

| over 4″ | 54 | 22 | 30 | ||

|

QQ-B-637

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| Half-Hard | up to 1/2″ | 60 | 27 | 22 | |

| over 1/2″ to 1″ | 60 | 27 | 25 | ||

| over 1″ to 2″ | 58 | 26 | 25 | ||

| over 2″ to 3″ | 54 | 25 | 25 | ||

| over 3″ to 4″ | 54 | 22 | 27 | ||

| over 4″ | 54 | 22 | 30 | ||

|

SHEET/PLATE

|

|||||

|

Commercial

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| M20 / O25 | up to 3″ | 50 | 20 | 35 | |

| over 3″ to 5″ | 50 | 18 | 35 | ||

|

QQ-B-639

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| Soft | up to 3/8″ x up to 30″ wide | 52 | 20 | 30 | |

| Soft | up to 3/8″ x over 30″ wide | 50 | 20 | 35 | |

| Soft | over 3/8″ x all widths | 50 | 20 | 35 | |

| Half-Hard | up to 3/8″ x up to 30″ wide | 60 | 35 | 20 | |

| Half-Hard | up to 3/8″ x over 30″ wide | 57 | 28 | 30 | |

| Half-Hard | over 3/8″ x all widths | 54 | 25 | 30 |

Compositions for C464 Naval Brass

|

COMMERCIAL

|

|||||||

| UNS No. | Copper + Silver | Tin | Lead | Iron | Zinc | ||

| C46400 | 59.0-62.0 | 0.50-1.0 | 0.20 max | 0.10 max | remainder | ||

| QQ-B-637 | |||||||

| UNS No. | Copper + Silver | Tin | Lead | Iron | Other elements total | Zinc | |

| C46400 | 59.0-62.0 | 0.50-1.0 | 0.20 max | 0.10 max | 0.10 max | remainder | |

| QQ-B-639 | |||||||

| UNS No. | Copper + Silver | Tin | Lead | Iron | Other elements total | Zinc | |

| C46400 | 59.0-62.0 | 0.50-1.0 | .20 max | 0.10 max | 0.10 max | remainder |

Physical Properties for C464 Naval Brass

| Density @ 68o F | 0.304 lb/in3 |

| Melting Range | 1630-1650o F |

| Hot Formability | Excellent |

| Cold Formability | Fair |

| Machinability rating (C360 = 100) | 30 |

| Brazing | Excellent |

| Soldering | Excellent |

| Gas-shielded arc welding | Fair |

| Oxy-acetylene welding | Good |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Not recommended |

| Resistant welding: spot and seam | Good |

| Resistance Welding: butt | Good |

Applications for C464 Naval Brass

|

* Tubesheets

|

| * Baffles |

|

* Valve Stems

|

|

* Pump Bodies

|

|

* Impellers

|

|

* Heat Exchangers

|

|

* Fasteners

|

|

* Mold Plates

|

|

* Wear Plates

|

|

* Decorative Fascia

|

|

* Antimicrobial Surfaces

|