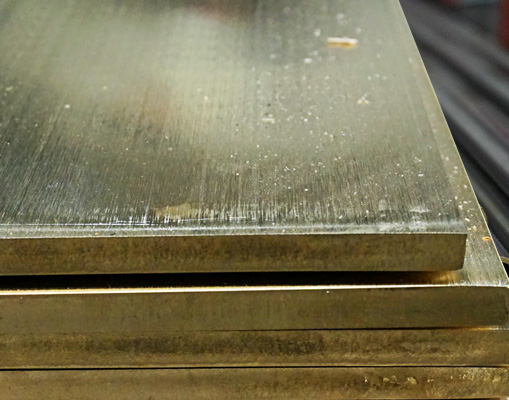

C36500 Leaded Muntz is copper, alloyed with zinc, tin and lead. Muntz metal has strength and corrosion resistance similar to C46400 Naval Brass but the higher lead content results in better machinability. C365 Muntz metal found historical prominence in the shipbuilding industry, primarily as a hull liner. C36500 Leaded Munts was adopted by the pressure vessel industry and is still, for many manufactures, the preferred alloy for tubesheets and condenser/cooler plates. Because of its warm reddish gold hue and corrosion resistance, 365 Muntz also has numerous decorative and architectural applications.

Marmetal stocks C36500 Muntz Metal Plate

Available Shapes for C36500 Leaded Muntz:

Specifications for C36500 Muntz Metal

| ASTM | ASME | |

| Plate | B-171 | SB-171 |

Mechanical Properties for C36500 Leaded Muntz

| Plate | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| M20 | 3″ and under | 50 | 20 | 35 | |

| O25 | over 3″ to 5″ | 50 | 18 | 35 |

Compositions for C36500 Muntz Metal

| UNS No. | Copper + Silver | Tin | Lead | Iron | Zinc |

| C36500 | 58.0-61.0 | 0.25 max | 0.25-0.70 | 0.15 max | Remainder |

Physical Properties for C36500 Muntz Metal

| Density @ 68o F | 0.304 lb/in3 |

| Melting Range | 1625o -1650o F |

| Hot Formability | Good |

| Cold Formability | Limited |

| Machinability rating (C360 = 100) | 60 |

| Brazing | Good |

| Soldering | Excellent |

| Gas-shielded arc welding | Fair |

| Oxy-acetylene welding | Fair |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Not recommended |

| Resistant welding: spot and seam | Not recommended |

| Resistance Welding: butt | Fair |

Applications for C36500 Muntz Metal

|

* Condensers

|

|

* Evaporators

|

|

* Tubesheets

|

|

* Heat Exchangers

|

|

* Fasteners

|

|

* Feedwater Heaters

|

|

* Architectural

|