C110 Copper, also known as Electrolytic Tough Pitch, is 99.90% pure copper. ETP 110 is one of the most commonly used commercially pure coppers. C11000 copper has one of the highest electrical conductivity ratings, in excess of 100%IACS. ETP C110 copper also has exceptional thermal conductivity and demonstrates good corrosion resistance. C110 ETP copper has a wide range of uses, including applications in architectural, industrial, electrical, automotive and construction industries.

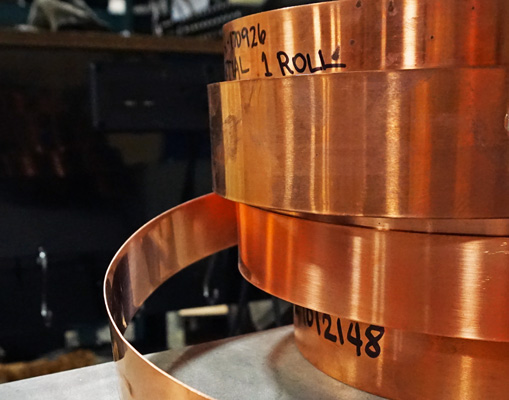

Marmetal stocks C11000 ETP Copper in Plate, Sheet, Strip, Coil, Pipe and Bar forms.

Specifications for C11000 ETP Copper

| ASTM | ASME | AMS | SAE | |

| Bar / Rod | ASTM B187 | ASME SB133 | SAE J461 | |

| Plate / Sheet | ASTM B152 | AMS 4500 | SAE J463 | |

| Pipe / Tube | ASTM B188 |

Mechanical Properties for C11000 ETP Copper

|

ROD – Round

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | TENSILE, KSI, MAX | Elong. % Min | |

| H04 | up to 3/8″ | 45 | 60 | 12 | |

| over 3/8″ to 1″ | 40 | 55 | 12 | ||

| over 1″ to 2″ | 35 | 50 | 15 | ||

| over 2″ to 3″ | 33 | 48 | 15 | ||

| over 3″ “ | 30 | 48 | 15 | ||

|

BAR – Square and Rectangular

|

|||||

| TEMPER | SIZE | TENSILE, KSI, MIN | TENSILE, KSI, MAX | Elong. % Min | |

| H02 | Up to 3/8″ x 4″ wide | 37.5 | 50 | 10 | |

| All other sizes | 33 | 50 | 15 | ||

|

PLATE and SHEET

|

|||||

| TEMPER | COMMON NAME | TENSILE, KSI, MIN | TENSILE, KSI, MAX | Rockwell, F Scale | |

| H00 | Eighth Hard | 32 | 40 | 54-82 | |

| H01 | Quarter Hard | 34 | 42 | 60-84 | |

| H02 | Half Hard | 37 | 46 | 77-89 | |

| H03 | Three-quarter Hard | 41 | 50 | 82-91 | |

| H04 | Hard | 43 | 52 | 86-93 | |

| H08 | Spring | 50 | 58 | 91-97 | |

| M20 | Hot Rolled | 30 | 38 | up to 75 | |

| O25 | HR and Annealed | 30 | 38 | up to 65 |

Compositions for C11000 ETP Copper

|

COMMERCIAL

|

||

| UNS No. | Copper | |

| C11000 | 99.90 min |

Physical Properties for C11000 ETP Copper

| Density @ 68o F | 0.322 lb/in3 |

| Melting Range | 1949-1981o F |

| Hot Formability | Excellent |

| Cold Formability | Excellent |

| Machinability rating (C360 = 100) | 20 |

| Brazing | Good |

| Soldering | Excellent |

| Gas-shielded arc welding | Fair |

| Oxy-acetylene welding | Not recommended |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Not recommended |

| Resistant welding: spot and seam | Not recommended |

| Resistance Welding: butt | Good |

Applications for C11000 ETP Copper

| * Roofing |

| * Gutters |

|

* Radiators

|

|

* Switches

|

|

* Conductors

|

| * Busbars |

|

* Magnet Wire

|

|

* Connectors

|

|

* Terminals

|

|

* Contacts

|

| * Tacks |

|

* Fasteners

|

|

* Printing Rolls

|

|

* Heat Exchangers

|

|

* Cookware

|