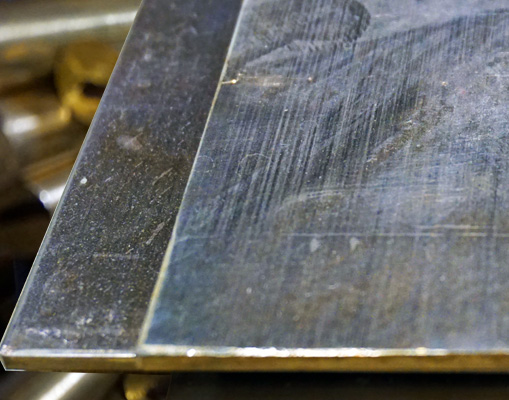

90/10 Cupro-Nickel is a copper-nickel alloy that shows good resistant to stress corrosion. Due to the addition of small amounts of iron and manganese, C706 CuNi is often used when an application will involve high-velocity

seawater. 90-10 Copper-nickel demonstrates good hot and cold working properties and is readily weldable. Typical 90/10 CuNi application in the chemical and marine industries include tubes and tubesheets for condensers, evaporators and heat exchangers. 90/10 Copper-Nickel is inherently antimicrobial, making it a good choice for touch surface applications.

seawater. 90-10 Copper-nickel demonstrates good hot and cold working properties and is readily weldable. Typical 90/10 CuNi application in the chemical and marine industries include tubes and tubesheets for condensers, evaporators and heat exchangers. 90/10 Copper-Nickel is inherently antimicrobial, making it a good choice for touch surface applications.

Marmetal stocks C706 90/10 Copper Nickel in Sheet, Plate, Bar, Pipe and Condenser Tube form, as well as Flanges, Fittings, Forgings and Castings.

Specifications for C706 90/10 Copper-Nickel

| ASTM | ASME | Military | |

| Bar | ASTM B151 | ASME SB-151 | MIL-C-15726 |

| Forging | MIL-C-24679 | ||

| Sheet | ASTM B171 | ASME SB-171 | MIL-C-15726 |

| Plate | ASTM B171 | ASME SB-171 | MIL-C-15726 |

| Pipe | ASTM B466 | ASME SB-466 | MIL-T-16420 |

| Tube | ASTM B111 | ASME SB-111 | MIL-T-15005 |

Mechanical Properties for for C706 90/10 Copper-Nickel

| BAR – Round, Hex and Square | |||||

| Commercial | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O60 | All Sizes | 38 | 15 | 30 | |

| H04 | up to 3/8″ | 60 | 38 | 10 | |

| over 3/8″ to 1″ | 50 | 30 | 15 | ||

| over 1″ to 3″ | 40 | 15 | 30 | ||

| over 3″ to 5″ | 38 | 15 | 20 | ||

| MIL-C-15726 | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O60 | All Sizes | 38 | 15 | 30 | |

| H04 | up to 3/8″ | 60 | 38 | 10 | |

| over 3/8″ to 1″ | 50 | 30 | 15 | ||

| over 1″ to 3″ | 40 | 15 | 30 | ||

| SHEET/PLATE | |||||

| Commercial | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| M20 / O25 | up to 2-1/2″ | 40 | 15 | 30 | |

| over 2-1/2″ | 40 | 15 | 30 | ||

| MIL-C-15726 | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O60 | up to 3/16″ | 38 | 15 | 25 | |

| M20 Soft | over 3/16″ | 38 | 15 | 30 | |

| H01 | up to 3/16″ x 24″ wide | 55 | 30 | 10 | |

| H01 | up to 3/16″ x over 24″ wide | 47 | 25 | 10 | |

| M20 Hard | up to 1/2″ x over 24″ wide | 47 | 25 | 15 | |

| M20 Hard | over 1/2″ to 3″ x all widths | 40 | 17 | 20 | |

| M20 Hard | over 3″ to 5″ x all widths | 38 | 15 | 20 | |

| PIPE | |||||

| Commercial | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O60 | All Sizes | 38 | 13 | N/A | |

| H80 | All Sizes | 50 | 40 | N/A | |

| MIL-T-16420 | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O60 | up to 4-1/2″ | 38 | 15 | 30 | |

| over 4-1/2″ | 38 | 13 | 30 | ||

| TUBE | |||||

| Commercial | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O61 | All Sizes | 40 | 15 | N/A | |

| MIL-T-15005 | |||||

| TEMPER | SIZE | TENSILE, KSI, MIN | YIELD@0.5%, KSI, MIN | Elong. % Min | |

| O61 | All Sizes | 40 | 15 | N/A |

Compositions for C706 90/10 Copper-Nickel

|

COMMERCIAL

|

|||||||||||

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | ||

| C70600 | remainder | 9.0-11.0 | 1.0 max | 0.05a max | 1.0-1.8 | 1.0a | |||||

| C70620 | 86.5 min | 9.0-11.0 | 1.0 max | 0.02 | 1.0-1.8 | 0.5 max | 0.02 max | 0.02 max | 0.05 max | ||

|

aFor subsequent welding application, max levels are: Zinc 0.50, Lead 0.02, Phosphorus 0.02, Sulfur 0.02, Carbon 0.05

|

|||||||||||

|

MIL-C-15726

|

|||||||||||

| UNS No. | Copper | Nickel | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | Cu + plus elements with specific limits, min | |

| C70600 | 86.5 min | 9.0-11.0 | 1.0 max | 0.02 | 1.0-1.8 | 0.5 max | 0.02 max | 0.02 max | 0.05 max | 99.5 | |

|

MIL-T-16420

|

|||||||||||

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | Cu + plus elements with specific limits, min | |

| C70600 | 86.5 min | 9.0-11.0 | 1.0 max | 0.02 | 1.0-1.8 | 0.5 max | 0.02 max | 0.02 max | 0.05 max | 99.5 | |

|

MIL-T-15005

|

|||||||||||

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | ||

| C70600 | remainder | 9.0-11.0 | 1.0 max | 0.05 max | 1.0-1.8 | 1.0 max |

Physical Properties for C706 90/10 Copper-Nickel

| Density @ 68o F | 0.323 lb/in3 |

| Melting Range | 2010-2095o F |

| Hot Formability | Good |

| Cold Formability | Excellent |

| Machinability rating (C360 = 100) | 20 |

| Brazing | Good |

| Soldering | Excellent |

| Gas-shielded arc welding | Excellent |

| Oxy-acetylene welding | Not recommended |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Good |

| Resistant welding: spot and seam | Good |

| Resistance Welding: butt | Good |

Applications for C706 90/10 Copper-Nickel

|

* Condensers

|

|

* Evaporators

|

|

* Tubesheets

|

|

* Valve Bodies

|

|

* Pump Bodies

|

|

* Impellers

|

|

* Fire Supression Systems

|

|

* Heat Exchangers

|

|

* Fasteners

|

| * Fittings |

| * Flanges |

|

* Architectural

|

|

* Antimicrobial Surfaces

|