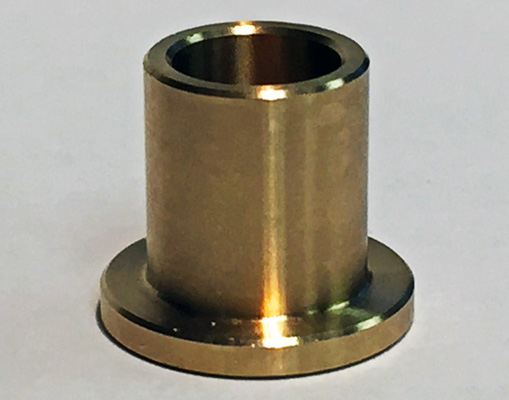

C93200 High-Leaded Tin Bronze, also known as SAE 660 Bronze, is the most widely used bearing bronze alloy. The lead found in CDA 932 Tin Bronze contributes to this alloys excellent machinability and good anti-friction properties. C93200 has reasonable corrosion resistance to seawater and brine. C932 Bronze is available as centrifugal cast, continuous cast and sand cast. CDA 932 High-Leaded Tin Bronze is ideally suited for high speed, light duty applications, including washers, bushings, bearings, fittings, pump impellers and fixtures.

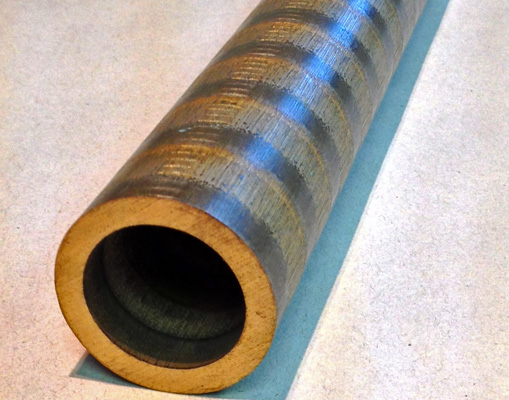

Marmetal stocks C93200 High Leaded Tin Bronze in bar and cast hollow tube forms.

Specifications for C93200

| ASTM | MILITARY | |

| Centrifugal Cast | ASTM B271 | QQ-C-390 |

| Continuous Cast | ASTM B505 | QQ-C-390 |

| Sand Cast | ASTM B548 | QQ-C-390 |

Mechanical Properties for for C93200

| Form | Specification | Tensile, min ksi (MPa) | Yield, min ksi (MPa) |

Elongation in 2”, % min

|

| Centrifugal Cast | ASTM B271 | 30 (207) | 14 (97) | 15 |

| Continuous Cast | ASTM B505 | 35 (241) | 20 (138) | 10 |

| Sand Cast | ASTM B584 | 30 (207) | 14 (97) | 15 |

Compositions for C93200 High Leaded Tin Bronze

| UNS No. | Copper | Tin | Lead | Zinc | Nickel incl. Cobalt | Iron | Aluminum | Antimony | Sulfur | Phosphorus | Silicon |

| C93200 | 81.0-85.0 | 6.3-7.5 | 6.0-8.0 | 2.0-4.0 | 1.0 max | 0.20 max | 0.005 | 0.35 max | 0.08 max | 1.5 |

0.005 max

|

Physical Properties for C93200 High Leaded Tin Bronze

| Melting Point – Liquidus°F | 1790 |

| Melting Point – Solidus°F | 1570 |

| Densitylb/cu in. at 68°F | 0.322 |

| Specific Gravity | 8.91 |

| Electrical Conductivity% IACS at 68°F | 12 |

| Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 33.6 |

| Coefficient of Thermal Expansion 68-21210⁻⁶ per °F (68 – 212°F) | 10 |

| Specific Heat CapacityBtu/ lb /°F at 68°F | 0.09 |

| Modulus of Elasticity in Tensionksi | 14500 |

Applications for C93200 High Leaded Tin Bronze

|

* Bushings

|

|

* Bearings

|

|

* Wearplates

|

|

* Impellers

|

|

* Pump Parts

|

|

* Marine Products

|

| * Valves |

|

* Rolling Mill Bearings

|

|

* Hydraulic Press Main Liners

|

|

* Hydraulic Press Stuffing Box

|

|

* Thrust Washers

|

|

* TrunionBearings

|